Concept to Completion

Kaufman Container is known in the industry as your one stop shop for all your packaging needs. We can assist you in every step of the way from concept to completion.

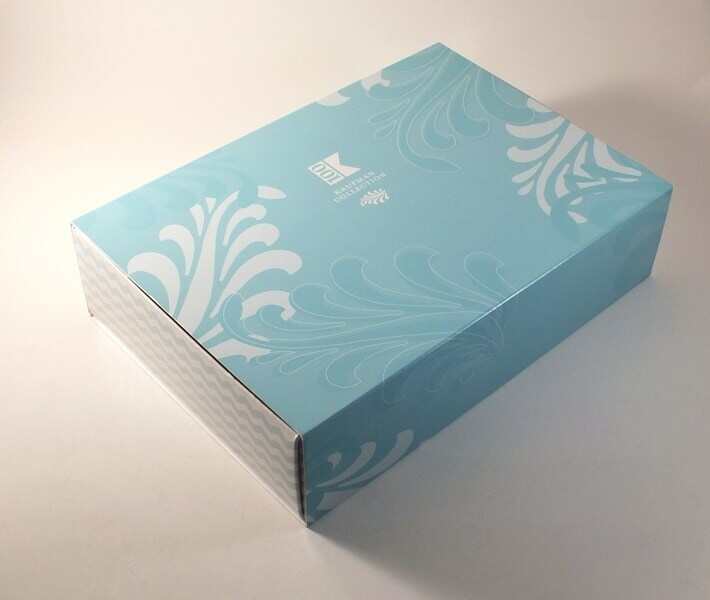

The picture below features our “Deco Kit” and it truly exemplifies our vast capabilities as a full source packaging provider. Every component in this kit is supplied by Kaufman Container including the container, closure, decoration and even the box itself. The box contains three different components: the base, insert, and sleeve. The insert was completely customized to hold the decorated packages in their corresponding locations. Different box styles can be created to fit a customer’s packaging needs and can also be customized to hold various types of products.

Our “Deco Kit” does an extraordinary job in showcasing our in-house decorating capabilities. With over 50 pieces of equipment, we are one of the largest decorators in North America. Each individual item in this kit highlights a unique decorating technique completed at Kaufman Container. Below, we will break down each item and explain all of the components and processes involved.

Item #1: Pressure Sensitive Labeling: In this package, a pressure sensitive label is applied to a 2 oz metal can. For large volumes, our PS labels are applied by automatic inline machines, but we can also accommodate smaller volumes with a semi-automatic machine. By choosing a pressure sensitive label, you will achieve superior graphics and high speed production. Some other forms of labeling we can offer include booklets & sleeve labels.

Item #2: Heat Shrink Labeling: In this package, a shrink sleeve is applied to a 125 ml PET cylinder. At Kaufman, the label is robotically placed around the container and then is sent through a steam tunnel where the label “shrinks” to conform to the shape of the container. There are several advantages to heat shrink labeling most notably the appearance. This type of decoration encourages bright & colorful graphics and it allows for 360 degree coverage of the package.

Item #3: Roll Stamping: In this package, the same 125 ml PET Cylinder uses both roll stamping & screen printing to provide a unique & elegant appearance. We can utilize the roll stamping machine in two unique ways by offering a variety of foils and patterns. The first being a metallic or holographic 360 degree foil that wraps around the container or closure. An alternative would be for us to stamp a logo directly onto the face of a container.

Item #4: Screen Printing on Closure: Kaufman has the capability to screen print on multiple materials, shapes & sizes. In this package, both the 50 ml PETG jar and the PP closure are screen printed two colors. In addition to printing on plastic containers & closures, Kaufman is also able to screen print on glass, metal and tubes.

Item #5: Screen Printing: This package demonstrates our ability to screen print on a 3 oz glass votive. We can accommodate both large and small runs on our automatic & semi-automatic machines. With multi-color capabilities and ability to print complex designs, screen printing is one of our most popular decorating techniques.

Send me a Deco Kit!